Introduction

Kenya introduced the Buy Kenya Build Kenya Strategy six years ago to promote the consumption of locally produced goods and services, create employment, and reduce the reliance on imports. The Buy Kenya, Build Kenya Strategy provides a roadmap to realize the purchase of locally produced goods and services by instilling patriotism and prioritizing Kenyan products to strengthen the local market. The main commodities targeted in the strategy are agricultural products, construction materials, the textile industry, pharmaceutical and health products, furniture and information and communication technology. Five of the key areas identified to ensure the initiative’s success were: legal and regulatory framework to guide public procurement; an enabling business environment; market access for locally produced goods and services; and advocacy and creation of institutional frameworks that ensure sustainability.

The Buy Kenya Build Kenya strategy provides subsidies and incentives to local producers in targeted sectors and enhances quality infrastructure to produce quality and competitive goods and services. It has also created an enabling business environment by safeguarding intellectual property rights, increasing investment in industrial research and development, innovation and technology transfer.

Supporting the Buy Kenya and Build Kenya Initiative

The government issued a directive to procure armed forces uniforms and footwear from local manufacturers, thereby stimulating the growth of the country’s textiles and leather industries. This initiative resulted in the creation of a substantial number of employment opportunities, particularly for the youth, as manufacturers expanded their workforce to meet the heightened demand for domestically produced military apparel. Moreover, the “Made in Kenya” label reinforced the commitment to support domestic industries and ensure high quality production of essential security-related attire.

Moreover, in 2019 through the Ministry of Foreign Affairs, the government mandated civil servants to wear “Made in Kenya” outfits to work every Friday and during public holidays. This directive emphasized the government’s commitment to boosting the domestic textile sector, encouraging the production of high-quality goods, and creation of local employment opportunities. Former President Uhuru even donned authentic Kenyan print shirts, signaling his personal endorsement of domestically produced fashion. This served as a symbol of his commitment to the initiative, inspiring others to embrace locally made products and contribute to the country’s economic growth and cultural identity. All these initiatives fostered a sense of national pride and self-reliance, reinforced the idea of promoting locally made products, contributing to economic growth, and instilling a sense of national pride to both civil servants and citizens.

Further, the Buy Kenya Build Kenya mandates that 40% of the government’s procurement be sourced locally. This has seen institutions such as Ministries, Departments and State Agencies (MDAs), for instance, the Ministry of Defense procure uniforms with local textile institutions at Rivatex and shoes from Bata Shoe Company. The Administration Police had uniforms sewed by Kitui County Textile. Kenya Power procured over 377,000 poles locally to drive its electrification programme and KIPPRA procured staff t-shirts from the National Youth Service for its 6th Annual Regional Conference. Several government institutions continue to purchase locally assembled vehicles from Toyota, Mobius, and Volkswagen, among others. In response to the increasing importance of the Buy Kenya Build Kenya, the Kenyan Senate this year sought comprehensive insights from the Committee on Trade, Industrialization, and Tourism. The Senate requested for a detailed statement underlining the progress on the implementation by the National government to ensure the effective execution of the initiative.

The government has created an enabling business environment and enhanced market access to micro and small enterprises (MSMEs) through policy directives that give them preferential treatment in public procurement. The National Treasury reviewed the Public Procurement and Disposable Regulations of 2011, the Public Procurement and Disposal (PPDA) Act 2015 and the Access to Government Procurement Opportunities to incorporate the requirement mandating that a minimum of 40% of all government procurement budgets also be committed to locally produced goods and services. To reinforce this, all MDAs are required to submit quarterly reports on implementation progress. During the COVID-19 period, local manufacturers increased production of critical items such as facemasks and protective gear to meet the then-increasing demand. The buying of local products from local businesses supports growth, especially MSMEs, which account for 45% of Kenya’s GDP and employ up to 80% workforce. The government has partnered with several private sector players and development partners to organize several exhibitions that allow local businesses to showcase local products. Top of Form

Implementation Gaps

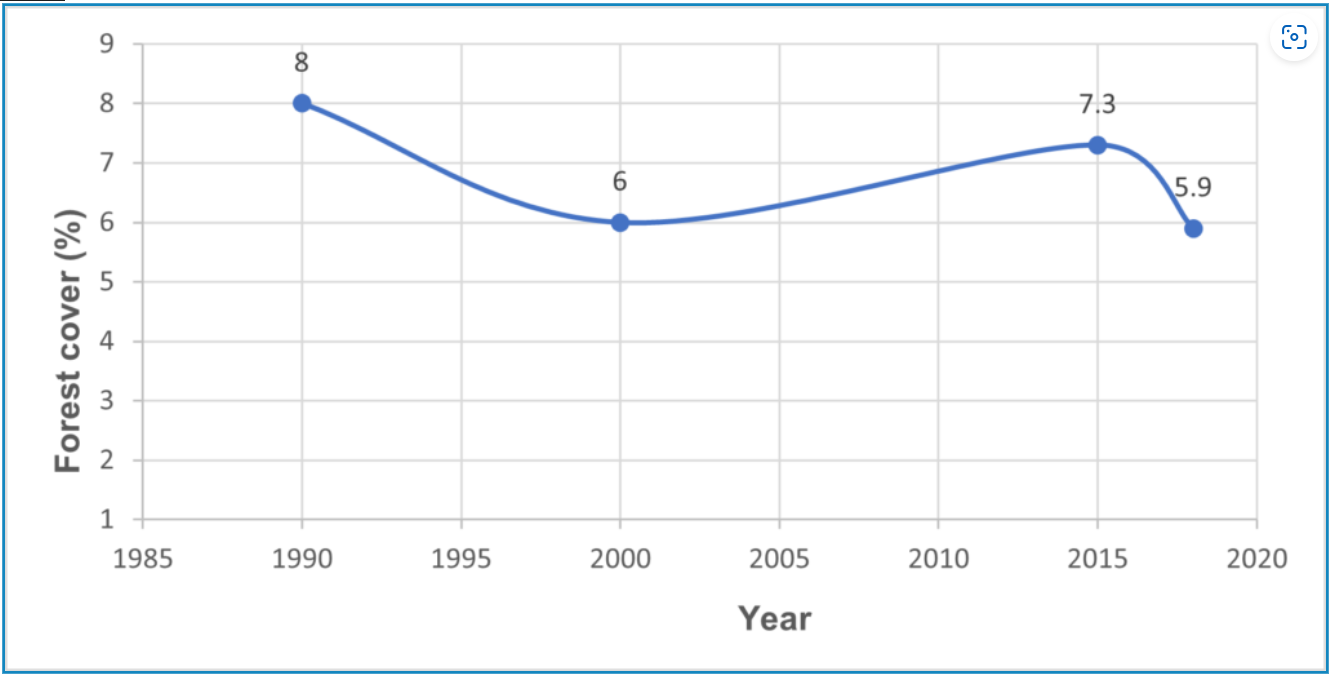

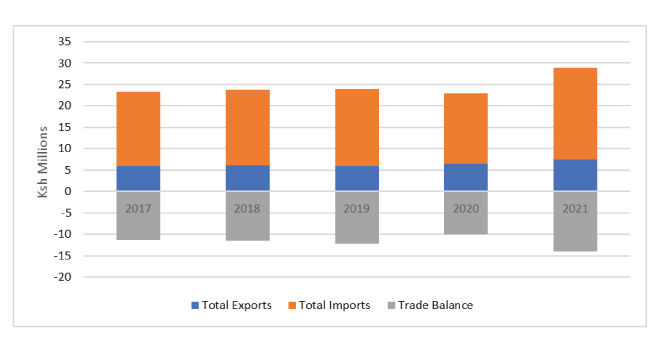

While the Buy Kenya, Build Kenya initiative has great potential in promoting sustainable development in the country, it still faces challenges in its implementation. Inadequacies in mitigating excess imports into the country suppress consumption of locally produced goods and have an adverse effect on trade imbalance as shown in Figure 1.

Figure 1: Kenya trade imbalance between 2017-2021

Data Source: Central Bank of Kenya (2022)

For instance, the textile industry heavily relies on imported raw materials whose prices and availability are determined by the global market, which is a limiting factor. With support from the government, the textile industry is currently able to sell its products locally. However, other companies in the special economic zones that manufacture products for export are unable to sell their products locally, which leads to heavy reliance on secondhand clothes also known as “Mitumba”. Secondhand apparel poses a threat to the Kenyan textile industry as they are affordable, hence their demand has been increasing steadily in 2022. Secondhand clothes registered an 18% increase in value of imports from 16.9 billion in 2018 to 19.9 billion in 2022 (KNBS, 2023).

The Public Service Commission 2021 report on the status of compliance indicates that 86% of government institutions implement the Buy Kenya, Build Kenya initiative by awarding tenders for the purchase of locally produced goods. However, the compliance rate was at 22% contrary to what is provided in the PPDA (2015). This shows that not all government institutions are compliant, and there is room for improvement to meet the set threshold.

The initiative has focused on expanding MSMEs. However, they still face several challenges that limit their potential to scale up production and compete effectively. The domestic market’s competitiveness remains challenging due to low levels of productivity, an inconducive business regulatory environment and inadequate infrastructure development. Local businesses, especially ones operating in MSMEs, are unaware of the various reforms such as the Buy Kenya Build Kenya Initiative and are unable to fully take advantage. Even when they do, they are unable to meet the market demand or supply products meeting sanitary and phytosanitary standards. In addition, it is challenging to change the local consumer preference for imported goods due to their perceived quality and inconsistent standardization of locally produced commodities.

Conclusion and Recommendations

The Buy Kenya Build Kenya Initiative is essential to the Kenyan economy. Buying locally made products helps lift the economy by promoting investments and offering locally produced goods that meet the needs and wants of local consumers. The government can unlock the full potential of the domestic market in Kenya by:

- Reviving the cotton industry to reduce over-reliance on imports: Kenya’s textile industry relies on 80% of raw material imports because of low cotton production and under-utilization of existing factories. The government could provide subsidies and increase producer prices to incentivize cotton farmers to produce more and to promote the utilization of locally produced cotton. There is also need to impose tariffs on cotton imports and promote collaboration between farmers and textile manufacturers in the establishment of a sustainable supply chain.

- Supporting MSMEs by creating a conducive business environment and improved infrastructure: MSMEs have unmet financial needs. Therefore, it is imperative to enhance financial accessibility and develop robust support infrastructure to enhance productivity and globally competitive products. This can be done through targeted financial programmes that are specific to the needs of MSMEs, with minimal collateral requirements and flexible loan structures for business expansion. County governments in collaboration with MSEA and private/public entities could establish the necessary infrastructure that bolsters MSME productivity, including the provision of modern facilities and technology to streamline operational processes. To ensure MSMEs take advantage of government support programmes, there is need for targeted communication for awareness and having information on the eligibility criteria.

- Promotion of quality assurance: Consumers prefer imported products to locally produced products due to the perceived quality and the fact that they are cheaper. To counter this, it is important to establish and enforce robust quality standards for locally manufactured goods and implement certification to verify authenticity and quality of products to enhance consumer confidence.

Authors: Anna Muema, KIPPRA Young Professional

Elizabeth Mangéni, KIPPRA Young Professional